Gas emergency 0 800 028 800

Safety in the workplace, an area of the PARI 2025 safety strategy of Teréga

As part of our strategic safety approach, PARI 2025, workplace safety is one of our areas of action and commitment. The safety of the men and women who make up our teams and the partners who work on our sites is a collective commitment.

Health and safety in the workplace, “zero accidents” objective for Teréga

Workplace safety is one of our priorities. We have therefore set an ambitious and voluntary target, in line with our PARI 2025 strategy: “Zero accidents”. We work on several fields simultaneously, in order to assert an efficient way of operating.

A safety management system, certified ISO45001, is implemented to provide structure and method, with the desire to rely on a clarified and simplified reference system.

Another area is to promote participatory innovation so that creativity and innovation are a permanent source of improvement in safety and working conditions.

Finally, our other main focus is animation and acculturation for an optimal level of HSE skills and involvement. To move towards an integrated safety culture, the emphasis is placed on strong management leadership and the increased involvement of each of our employees.

How does Teréga make prevention a priority?

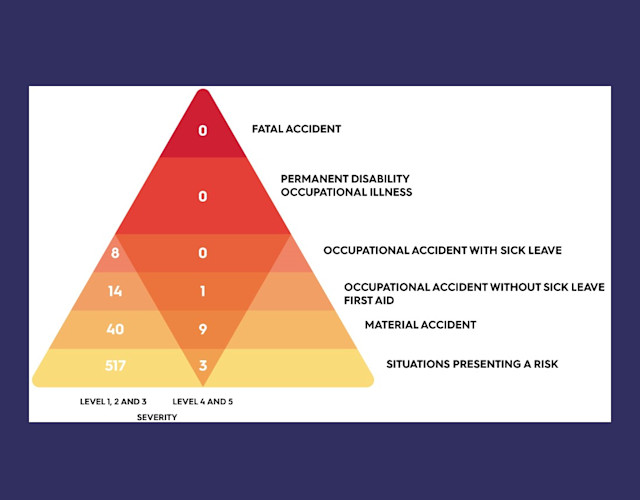

While prevention is a priority area of work, we are working in particular on the diamond concept of prevention. Its objective: to focus on the essential by graduating the seriousness of events.

We have also set up our own Health, Safety and Environment (HSE) accreditation system for suppliers. An initiative that aims to strengthen risk management and guarantee the same level of safety culture shared with our partners. We also rely on the MASE (Manual for the Improvement of Company Safety) certification or standards such as ISO45001, a safety management system standard.

The golden rules of safety at Teréga

Our conviction and commitment are that a risk situation must remain temporary, be avoided or eliminated. To meet this challenge, it is essential that each of our employees has the necessary means to be continuously proactive and remain vigilant. We have set up 12 golden rules, resulting from analysing our risks and occurring events, to define the basic rules associated with these risks. They involve:

Natural gas,

Movements,

Gestures and postures,

Protective equipment and tools,

Intervention management,

Change management,

Parallel human-machinery activity,

Earthworks/excavations,

Lifting and hoisting operations,

Lock-out/tag-out,

Work at height,

Set of temporary operational factors.

How does digital contribute to security at Terega?

In order to further strengthen prevention, we have also developed the use of digital tools:

a mobile application – TERA – with photo and geolocation, to report risk situations or any accident in real time,

a virtual reality tool, to train in the operation of delivery stations,

an e-learning approach for personal safety reception for drilling, storage centres and compressor stations.

Audrey BodinOccupational health and safety department managerOne of our priorities is to be continuously aware of the risks that our activities may represent. We owe it to ourselves to be irreproachable and show a constant high level of mastery.